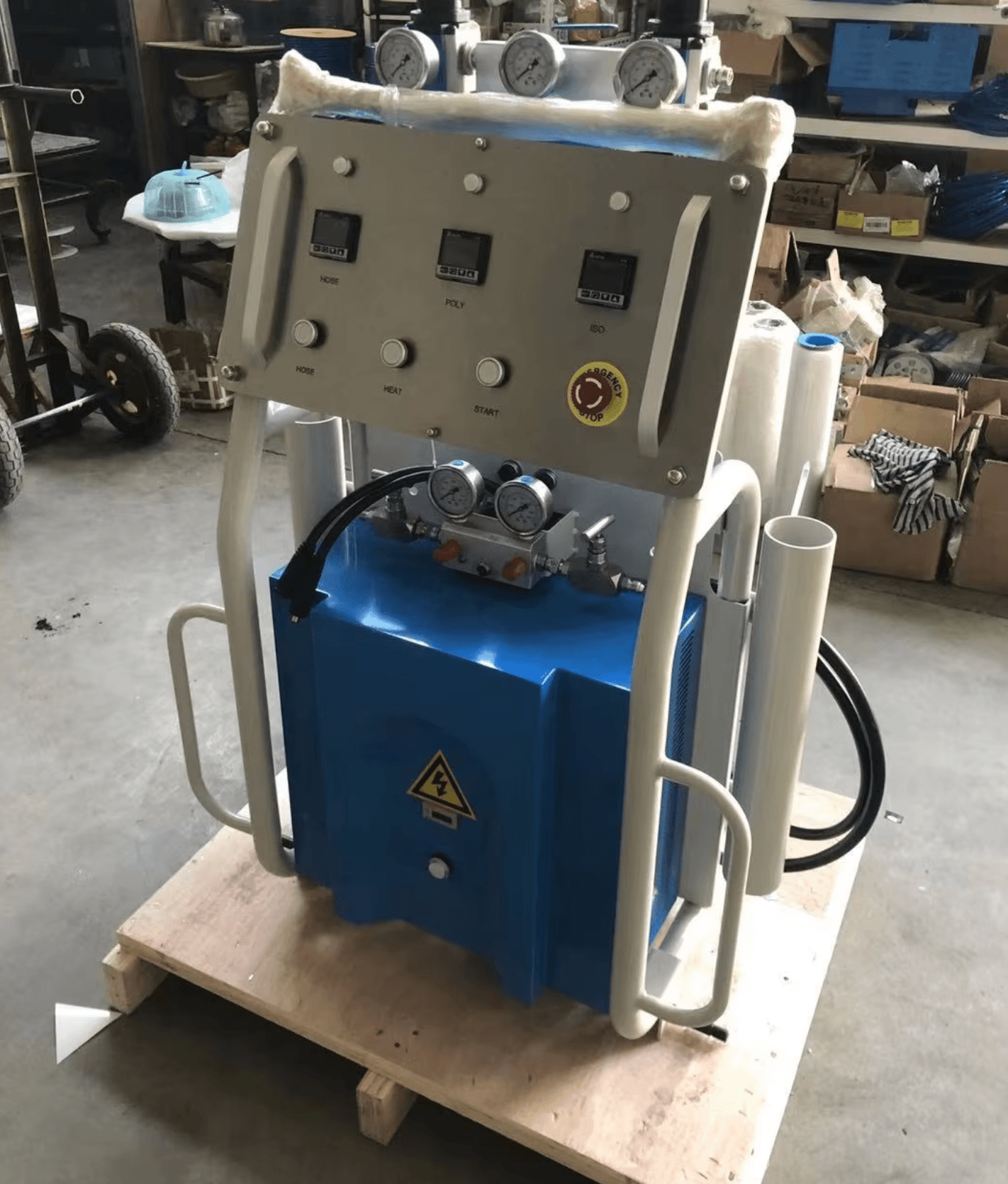

FD-411B

Cheap Pneumatic Polyurethane Foam Machine , mainly used for spraying polyurethane on walls and roofs, this product is mainly exported to Brazil, Russia

Product Details

Important attributes

standard configuration

Packaging and shipping information

Advanced and compact design of the pneumatic drive proportional unit,optimizedfor PU foam application scenarios.

Special configuration facilities allow easy access to all components, simplifying control functions while significantly reducing maintenance.

Two-part combination construction: two pumps, operated by air motors,operatingwithin a specific pressure ratio

Pressure ratio versus fluid pressure: e.g., a 25:1 pressure ratio provides 25 psi of fluidpressureper pound of air pressure.

Characteristics of traditional pneumatic equipment.

Strengths: Consistent dispensing of material as long as the mainframe diameter is adequate, provenand reliabletechnology

Shortcomings: Inability to adequately monitor pressure and reliance on operator observation of foam condition to ensureuniformdistribution

Scenarios: Preferred by startups (simple structure, lower price); FD-411B can be a perfectmatch forhigher production capacity after business expansion.

Optimizedspraying effect

Enlarged cylinder design for more uniform spraying andmixing

Consistent output pressure for uniform spraypattern

Quality andDurability

Electronic components and seals are imported brands, strong stability and long-term use is not easy tobreak.

Adhere to high-end positioning, reject low-enddistribution

Safety andCompatibility

The heated hose is equipped with a voltage protection function to ensure thesafety ofelectricity.

The spray gun and heating hose can be used universally with G/R/A/C/O to enhance thecompatibility ofthe equipment.

Intelligent control andoperation

Three independent heating zones (ISO, resin and hose heating)

Digital temperature control with precise heat adjustment for different chemical viscositymaterials

Maintains temperature set point for increasedproductivity

Practical featureset

Easy to use, operate andmaintain

Resettable counter for accurate tracking of material usage and cost management

Supplier Info

Jinan Xinling Intelligent Technology Co.

Professional Spraying Equipment Manufacturer

Contact Information

- 8618311346723

- sales@xinlingmechine.com

- Gaoxin District, Jinan City, Shandong Province (No. 188 Chunbo Road)